Your company's pneumatic

tube system provider,

from A to Z

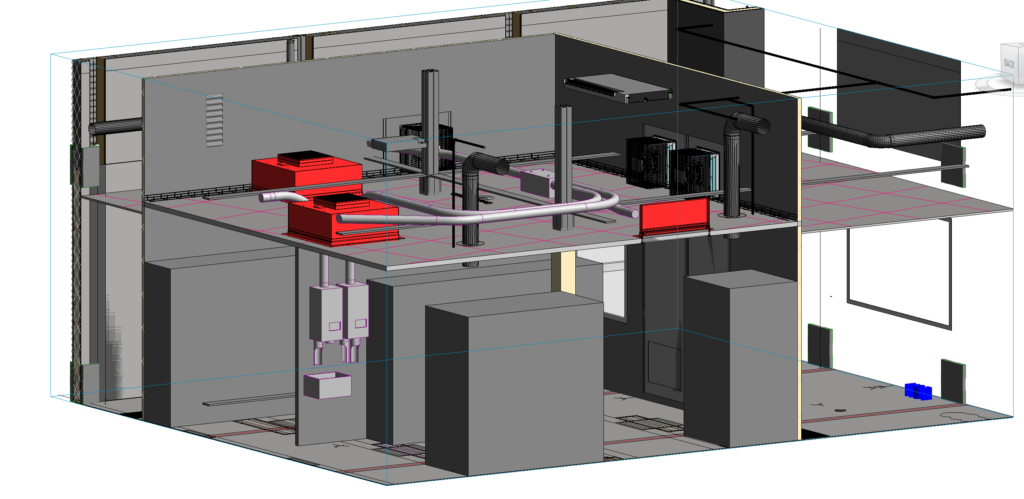

Design

We always start by closely listening to what the customer’s needs are. We then make a personalised design that matches the customer’s needs perfectly. That is how we build the perfect fit for your internal transportation system.

CONSULTANCY

Providing advice to engineering agencies forms an important link in our operations.

Based on our many years of experience in pneumatic tube systems, we provide valuable guidance in designing the ideal system layout, from the embryonic design stage of new projects right up to their realisation.

You can also rely on Aerocom Belgium’s consultants’ expertise for a tailor-made study with a view to renewing existing pneumatic tube systems, enhancing the transmission capacity and adding new technologies such as lab automation.

Implementing BIM management from the study stage up to the realisation is part of our company’s culture.

Installation

Our in-house installation teams are on call to respond to our customers’ needs quickly and efficiently. Our many years of experience allow us to successfully tackle even the most complex assignments. In locations where strict hygienic regulations are to be observed, such as hospitals, clean rooms and the food industry, we work closely with our customer to ensure we use appropriate working methods.

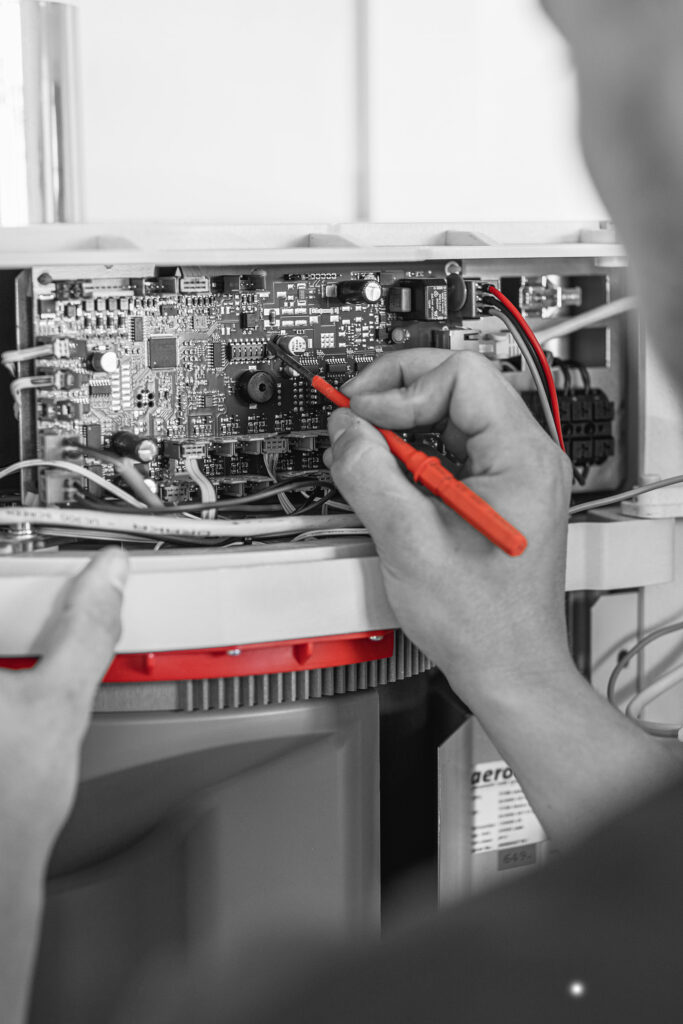

Service

Customers can call or email us at any time. We have an expert team at hand to respond, day in day out. Our service does not end with the sale of the custom-made design. We make sure your system is fully operational and running like clockwork, and we intervene whenever maintenance is required. If you run into problems, we quickly respond, also after the system has been installed.

If you need even more guarantees, you may choose to take out a full-coverage service contract with 24/7 cover for complete peace of mind. We have our in-house servicing team of field service engineers standing by day and night to help you out.

Validation of pneumatic tube systems

By using our CSC carrier – our ‘Camera-Sensor-Check’ carrier – we combine pneumatic flow measurements and video recordings.

Analysing these measurements allows to pinpoint the section in your system that is the most susceptible to risk, thus minimising the number of hospital tests required. This analysis reveals whether or not adjustments are necessary. Once the results of the most risk-prone route section are satisfactory, the system is validated.

Have a system that requires validation? Contact us for a personalised quotation.